Pakaflex UV resistant and Industrial Packaging

What We Do

What We Do

Pakaflex is an Australian owned and operated manufacturing company specialising in a range of UV resistant and industrial packaging products. Our focus is on innovation and service to meet the ever increasing market demands of our customers throughout Australia and New Zealand. Whatever your needs, you can be sure that Pakaflex will provide the service, innovation and savings to keep you coming back. Operating since 1989 were are committed to creating partnerships so that we can deliver the cost benefits of tailored solutions.

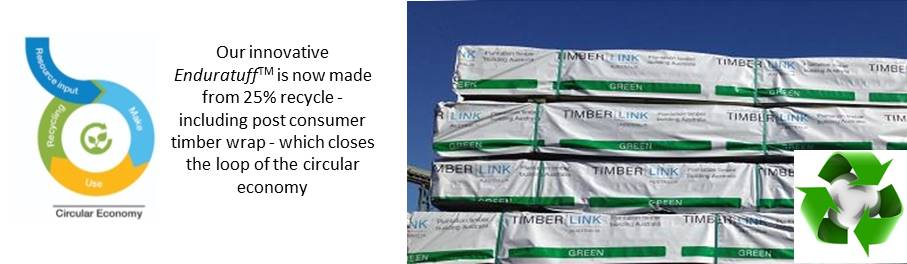

Circular Economy

Circular Economy

In 2021 Pakaflex commissioned a state of the art plastic film recycler. In partnership with Sustainability Victoria this machine recovers LDPE (recycle code 4, with very high print coverages) and is used to process both internal scrap and wrap returned to us from our customers. Already, this process has been in place for several years with several of our major partners, including AKD Softwoods. They are returning all their scrap wrap from their packing operations. The recovered material is utilised back into the same Enduratuff™ long life timber protection covers to provide a genuine closed loop or circular economy.

This investment also creates more than 2 totally new jobs at our main manufacturing facility in Dandenong.

New Investment on line

We are pleased to advise that our newest coxtruder was installed in November and has been immediately fully utilised! It has been of great assistance in improving turn-around times. You can see the latest automatic air-ring and extrusion control system from Europe. We still have some more exciting upgrades for 2023 coming!

Pakaflex Printer wins graduate of the year!

After our last successful (and award winning) printing apprenticeship programme we have already recruited a new batch of apprentices for the class of 2023 We are excited to have been recognised for our innovative print. For more information go to : www.print21.com.au/commercial/pakaflex-printer-lia-vic-graduate-of-year

Ausdeck goes for photographic wrap

We are proud to have helped AUSDECK patios and roofing make their product stand out!. With their new vibrant Blue and Green photographic printed wrap -it is clear that they are the premium supplier. This wrap is used to ship the product around Australia and it was made on our new 8 colour press. We […]